SG40:20 Scaffolding Yard Operations

NASC has produced comprehensive guidance for managing the scaffolding yard. The invaluable SG40: 20 document contains information on a wide range of issues across all aspects of yard management.

Understanding workplace hazards

Scaffolding yards are rife with potential hazards, including:

- Safety Hazards: Inadequate machine guards, unsafe workplace conditions, and unsafe work practices.

- Biological Hazards: Exposure to viruses, bacteria, fungi, and parasites.

- Chemical Hazards: Risks from solids, liquids, vapours, gases, dust, fumes, or mists.

- Ergonomic Hazards: Strains from repetitive and forceful movements, awkward postures, and improperly designed workstations.

- Physical Hazards: Noise, vibration, energy, weather conditions, heat, cold, electricity, radiation, and pressure.

- Psychosocial Hazards: Overwork, stress, bullying, and violence.

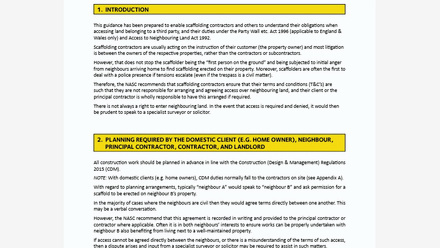

Risk management strategies

Effective risk management is crucial in mitigating these hazards. NASC recommends conducting comprehensive health and safety risk assessments. These assessments should identify potential risks and implement control measures to eliminate or minimise them. Communication of these assessments to all employees and contractors is vital.

Manual handling requires particular attention. Employers must conduct risk assessments and avoid tasks that could result in injury. The use of a written Yard Operations Manual can help retain essential company knowledge and ensure consistent safety practices.

Personal protective equipment (PPE)

PPE is a critical component in safeguarding workers against health and safety risks. Employers must assess the need for PPE through risk assessments and ensure that suitable equipment is provided, maintained, and used correctly. NASC recommends five-point PPE, including hard hats, high-visibility clothing, gloves, safety footwear, and eye protection.

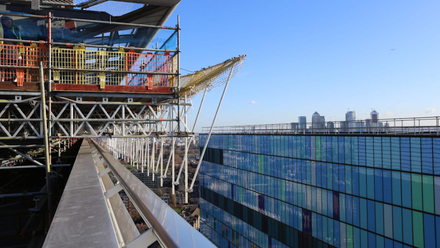

Optimising yard layout

A well-planned yard layout balances storage space and working space, facilitating efficient operations. Key areas include receiving new stock, unpacking, packing, transportation, hire and sale stock, usable stock, equipment maintenance, administration, and welfare facilities. Implementing a Traffic Management Plan (TMP) can minimise interactions between mobile plant and personnel, reducing the risk of injury.

Plant and equipment management

Proper management of work equipment, including scaffolding, hand tools, machines, and lifting equipment, is essential. Regular inspections and maintenance by competent personnel ensure that equipment remains safe and functional. Forklift trucks require thorough examinations and training for operators to prevent accidents.

Environmental protection

Environmental protection measures, such as the proper storage and inspection of intermediate bulk containers (IBCs) and bunded fuel tanks, are crucial. Regular inspections and compliance with legislation help prevent leaks and spills, protecting both the environment and human health.

Waste management

Effective waste management involves segregating waste into hazardous, non-hazardous, and inert categories. Recycling and reusing materials can significantly reduce landfill waste, protecting profit margins and addressing sustainability concerns.

Inspection, maintenance and storage of scaffolding material

Regular inspections and maintenance of scaffolding materials, including boards and fittings, ensure their safety and usability. Proper storage practices prevent damage and maintain the integrity of the equipment.

Workplace signage and communication

Clear and effective signage is essential for communicating safety information and directing personnel. Signs should comply with health and safety regulations and be prominently displayed to warn of hazards and provide instructions.

Provision of workplace welfare facilities

Providing adequate welfare facilities, such as toilets, washing facilities, drinking water, and rest areas, is fundamental to safeguarding workers’ health and wellbeing.

Emergency arrangements

Employers must develop and communicate emergency plans to handle foreseeable emergencies, such as fires, spills, and first aid incidents. Regular drills and training ensure that all personnel are prepared to respond effectively.

Statutory compliance

Compliance with health and safety legislation is a legal duty for employers. This includes maintaining records of accidents, fire management, fall arrest systems, water hygiene, electrical testing, and more. Regular inspections and adherence to regulations ensure a safe working environment.